FREQUENTLY ASKED QUESTIONS

Orders

Postage

Returns

Payment

Sizing

Leather

Orders

This varies on depending on several factors (your style, the time of year etc).

You will be given a general estimated production time on the listing of the jacket underneath the size selection box. Once your order is placed and confirmed by a member of our team, we will then give you a more specific estimated completion date for your order.

Typically, times get down to 6-8 weeks in the summer and 12-14 weeks in the winter. Sheepskins do tend to be longer in the winter as this is the most popular time for them, we recommend ordering mid-end of summer to ensure you have it that winter.

You will be given a general estimated production time on the listing of the jacket underneath the size selection box. Once your order is placed and confirmed by a member of our team, we will then give you a more specific estimated completion date for your order.

Typically, times get down to 6-8 weeks in the summer and 12-14 weeks in the winter. Sheepskins do tend to be longer in the winter as this is the most popular time for them, we recommend ordering mid-end of summer to ensure you have it that winter.

Yes, we have stock, used and vintage jackets ready to be dispatched on the same day if you order before 2pm. All these jackets are returnable if the fit is not correct. Please see our ‘ready to wear’ jacket section to view these jackets.

You will receive regular updates via email on your order throughout its journey, including confirming we have accepted your order, a prompt for you to confirm your final specs, letting you know when we begin work on your jacket and when your jacket is complete and ready for dispatch.

You can also log into your account area on our website to view which stage your jacket is currently at.

You can also log into your account area on our website to view which stage your jacket is currently at.

You can change your order right up until your final specs are confirmed (this is 14 days after your order is placed). After this, we cannot guarantee we will be able to amend your order as initial work may have started on your jacket.

You have a 14-day cooling off period where you can cancel your order and receive a full refund of your deposit.

After the 14-day period you can still cancel your order and receive a full refund provided we haven’t started any work on your jacket – if your jacket has entered production your deposit may be non-refundable.

After the 14-day period you can still cancel your order and receive a full refund provided we haven’t started any work on your jacket – if your jacket has entered production your deposit may be non-refundable.

Please get in touch with as soon as possible so we can try and come to arrangement e.g. a payment plan. If you don’t hear from you within a month of your jacket being made, there is a risk you will lose your deposit and we will add the jacket to our stock.

Postage

We ship worldwide via DHL courier, although depending on your location an alternative courier may be used.

Please give us a call and we can add your location to our database and let you know the postage cost over the phone.

This is dependent on the weight of the item(s) you are sending and your geographical location. Please see below:

‘Light’ items: scarves, gloves, belts, wallets etc

‘Medium’ items: knitwear, denim etc

‘Heavy’ items: leather jackets, boots etc

If your delivery location doesn’t fall into one of these districts (e.g. a non EU European nation) you will be charged based on the pricing band DHL applies to your location. You will be informed of the cost at the checkout.

Please note, postage charges shown are based on the heaviest single item in your basket. In the case of multiple items, if you have asked us to dispatch items as soon as possible (more than one dispatch) or you have more than one heavy item being sent together (e.g. two jackets) there may be additional postage charges to be applied depending on the additional cost charged by DHL in these instances. We will always contact you to confirm these charges with you before applying them and in no instance would it be more than a 2nd equal charge to the one displayed.

District

UK

EU

United States

Middle East/Africa

Canada

Russia/Asia

Australia/New Zealand/Pacific

Light

£7.50

£15.00

£20.00

£25.00

£30.00

£30.00

£35.00

Medium

£10.50

£22.50

£35.00

£35.00

£45.00

£55.00

£60.00

Heavy

£15.00

£30.00

£65.00

£75.00

£75.00

£95.00

£105.00

‘Light’ items: scarves, gloves, belts, wallets etc

‘Medium’ items: knitwear, denim etc

‘Heavy’ items: leather jackets, boots etc

If your delivery location doesn’t fall into one of these districts (e.g. a non EU European nation) you will be charged based on the pricing band DHL applies to your location. You will be informed of the cost at the checkout.

Please note, postage charges shown are based on the heaviest single item in your basket. In the case of multiple items, if you have asked us to dispatch items as soon as possible (more than one dispatch) or you have more than one heavy item being sent together (e.g. two jackets) there may be additional postage charges to be applied depending on the additional cost charged by DHL in these instances. We will always contact you to confirm these charges with you before applying them and in no instance would it be more than a 2nd equal charge to the one displayed.

UK: Usually next working day delivery after payment but can be the following working day depending on time of day the order is processed.

EU: Up to 5 days

Rest of the World: Up to 14 days

DHL will inform you of an estimated delivery date shortly after your order is processed by our dispatch team.

EU: Up to 5 days

Rest of the World: Up to 14 days

DHL will inform you of an estimated delivery date shortly after your order is processed by our dispatch team.

Yes, once your order has been fully processed by our dispatch team you will receive an email with a link to your tracking number.

The courier will try to deliver your package two more times.

You will have to contact them to let them know when you will be available to accept your parcel.

You will have to contact them to let them know when you will be available to accept your parcel.

Your postage charge covers the carriage of the goods from here to your door and does not include any calculation of the duty/sales tax which may or may not be applied in any country which we export to.

Each countries' government have their own laws, regulations, and tariffs which they levy on such imports of foreign goods.

This is beyond our control regardless of which country goods are shipped to and is down to each governments' policy concerning the importation of goods.

Each countries' government have their own laws, regulations, and tariffs which they levy on such imports of foreign goods.

This is beyond our control regardless of which country goods are shipped to and is down to each governments' policy concerning the importation of goods.

Returns

We accept returns on most goods returned within 30 days of receipt in the same condition they were purchased in.

Any jacket ordered from our ‘Ready to Buy’ section or any other ‘Stock’ item can be returned for an exchange, credit note or a full refund. The only exception is washed denim goods which we cannot accept returns on.

Any ‘Made to Order’ jacket made to standard measurements and materials can also returned for an exchange, credit note or a full refund.

With any ‘Made to Order’ jacket that has had custom measurement alterations and modifications, we can only offer a full exchange, credit note or refund if there is an error in the jacket make up, a fault in materials or the jacket doesn't meet client’s measurement specifications within the accepted tolerances.

If your made to order jacket has been made to the agreed specifications, we will review these on a case-by-case basis and usually accept a return (we will make you aware in advance of purchase if a heavily customised jacket is non-returnable) but the return will incur a minimum £ 50 restocking charge.

Any jacket ordered from our ‘Ready to Buy’ section or any other ‘Stock’ item can be returned for an exchange, credit note or a full refund. The only exception is washed denim goods which we cannot accept returns on.

Any ‘Made to Order’ jacket made to standard measurements and materials can also returned for an exchange, credit note or a full refund.

With any ‘Made to Order’ jacket that has had custom measurement alterations and modifications, we can only offer a full exchange, credit note or refund if there is an error in the jacket make up, a fault in materials or the jacket doesn't meet client’s measurement specifications within the accepted tolerances.

If your made to order jacket has been made to the agreed specifications, we will review these on a case-by-case basis and usually accept a return (we will make you aware in advance of purchase if a heavily customised jacket is non-returnable) but the return will incur a minimum £ 50 restocking charge.

Please contact us as soon as you’re aware you will need to process a return so we can log this on your order record and advise the next steps. We will ask you to print off and fill out this returns form, cutting off the top and sticking to the front of the box. This step is very important as the box needs to be clearly marked as a return - this is especially important for returns from outside of the UK so there aren’t any hold ups at customs. The bottom half should be placed inside the box for speed of processing the return at our end.

Please ensure that goods (especially jackets) are packed neatly and sent back in a box that they fit in to (ideally the same one it was sent in). It is vital that goods are not squashed into small boxes as damaged returned goods will impact your refund/exchange price.

Unless there is some fault in the goods you are returning, arranging the return and it’s cost will be your responsibility. Please send any returns/exchanges to:

Aero Leather Clothing

Greenbank Mill

Huddersfield Street

Galashiels

TD1 3AY

Scotland

Please ensure that goods (especially jackets) are packed neatly and sent back in a box that they fit in to (ideally the same one it was sent in). It is vital that goods are not squashed into small boxes as damaged returned goods will impact your refund/exchange price.

Unless there is some fault in the goods you are returning, arranging the return and it’s cost will be your responsibility. Please send any returns/exchanges to:

Aero Leather Clothing

Greenbank Mill

Huddersfield Street

Galashiels

TD1 3AY

Scotland

You will need to contact your customs office directly to claim back any duties/taxes you have been charged by them upon import. These charges are out of our control and each country has different processes and policies regarding claiming these charges back. We are unable to assist here beyond confirming your original dispatch information.

Please let us know as soon as possible so we can inform the courier of the correct address.

It’s important that you check over the delivery address you’ve supplied when you receive your dispatch confirmation email. If you’ve supplied the wrong address and the package ends up being delivered there you may be liable for additional charges in redirecting the package.

It’s important that you check over the delivery address you’ve supplied when you receive your dispatch confirmation email. If you’ve supplied the wrong address and the package ends up being delivered there you may be liable for additional charges in redirecting the package.

In cases where the item is damaged or defective in some way, we will reimburse you for your initial postage charge and arrange the pick-up/return of the item at our expense.

If you’d like to return a product where the product is of satisfactory quality, you will need to arrange and pay for this yourself. Any refund we are due you would not include outbound/return postage charges.

If you’d like to return a product where the product is of satisfactory quality, you will need to arrange and pay for this yourself. Any refund we are due you would not include outbound/return postage charges.

Payment

We accept most major debit and credit cards, including Visa, Mastercard, AMEX and Diners. We do not accept PayPal.

If you can’t pay by card, we can also accept payment by BACS using the following details and using your order number as the reference:

AERO LEATHER CLOTHING LTD

BANK OF SCOTLAND

SORT CODE: 80-08-88

ACCOUNT: 00184924

BIC: BOFSGB21087

IBAN: GB86 BOFS 8008 8800 184924

Please note, due previous history of issues we’ve had with card payments, purchases from Malaysia can only be paid by BACS.

If you can’t pay by card, we can also accept payment by BACS using the following details and using your order number as the reference:

AERO LEATHER CLOTHING LTD

BANK OF SCOTLAND

SORT CODE: 80-08-88

ACCOUNT: 00184924

BIC: BOFSGB21087

IBAN: GB86 BOFS 8008 8800 184924

Please note, due previous history of issues we’ve had with card payments, purchases from Malaysia can only be paid by BACS.

All monies paid to us are converted to Pounds Sterling (GBP).

Any customers wishing to pay in other currencies will ask their card supplier or bank to convert the money before payment. This may incur an admin charge and the value will of course be subject to fluctuating exchange rates.

Any customers wishing to pay in other currencies will ask their card supplier or bank to convert the money before payment. This may incur an admin charge and the value will of course be subject to fluctuating exchange rates.

When purchasing stock items and ready to buy jackets, your card will be charged in full at the checkout/point of order.

When purchasing made to order jackets, you can either pay the balance in full at the checkout or you can place a 25% deposit and pay the remainder of your balance when your jacket is complete (at the checkout, you can ask us to take the remainder automatically or receive a prompt to make the payment yourself).

When purchasing made to order jackets, you can either pay the balance in full at the checkout or you can place a 25% deposit and pay the remainder of your balance when your jacket is complete (at the checkout, you can ask us to take the remainder automatically or receive a prompt to make the payment yourself).

Sizing

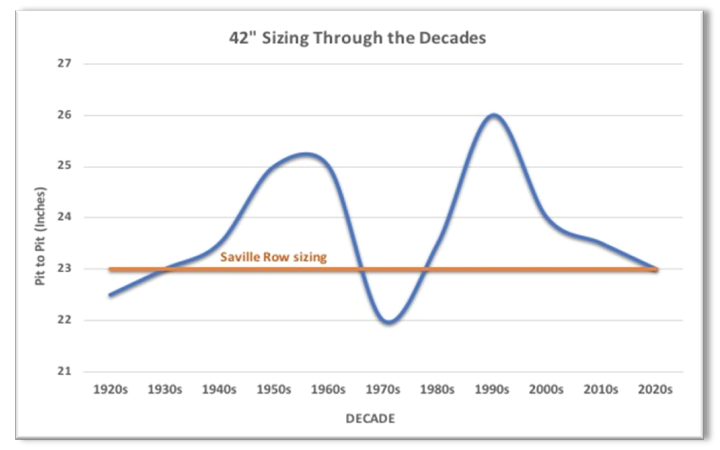

Sizing between manufacturers/country varies significantly and when added to the fact that our range covers a time period where sizing/fit also varied greatly, this means that this answer isn’t a straightforward one and very much depends on the style you are purchasing and the look you want to achieve.

Fit falls into two categories: “traditional tailored” and “fashion/design”. While traditional bespoke tailoring, Savile Row style, has altered very little in the past 100 years, fashion, and the perceived correct fit of clothing has varied considerably over the past century.

Your Aero will always fit as it would have been made and worn during the era the design dates from i.e. the size on the ticket represents how a jacket was “supposed to fit” during the era it was constructed.

A Size 42 1950s Highwayman is made to fit as it would if it been made in the 1950s, while a Size 42 1930s Highwayman is a complete recut to the style and manner of the 1930s and therefore, a far slimmer-fitting Size 42.

A general rule of thumb is that 1930s style jackets are cut closer to a ‘modern’ fit, whereas 1950s styles are roughly a size up.

Depending on the look or fit you want to achieve with a given style, this may mean sizing up/down from the size you may be accustomed to buying in modern styles. Don’t worry, our team are on hand to discuss the measurements you provide us and any sizing queries you might have before purchase.

Fit falls into two categories: “traditional tailored” and “fashion/design”. While traditional bespoke tailoring, Savile Row style, has altered very little in the past 100 years, fashion, and the perceived correct fit of clothing has varied considerably over the past century.

Your Aero will always fit as it would have been made and worn during the era the design dates from i.e. the size on the ticket represents how a jacket was “supposed to fit” during the era it was constructed.

A Size 42 1950s Highwayman is made to fit as it would if it been made in the 1950s, while a Size 42 1930s Highwayman is a complete recut to the style and manner of the 1930s and therefore, a far slimmer-fitting Size 42.

A general rule of thumb is that 1930s style jackets are cut closer to a ‘modern’ fit, whereas 1950s styles are roughly a size up.

Depending on the look or fit you want to achieve with a given style, this may mean sizing up/down from the size you may be accustomed to buying in modern styles. Don’t worry, our team are on hand to discuss the measurements you provide us and any sizing queries you might have before purchase.

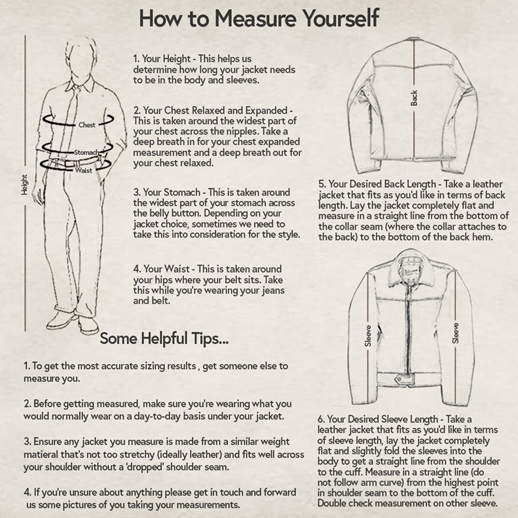

Before measuring, make sure you’re wearing what you would normally wear on a day-to-day basis under your jacket and to get the most accurate sizing results, get someone else to measure you.

As well as your height, we need the following body measurements to determine your correct sizing:

Chest Relaxed and Expanded: This is taken around the widest part of your chest across the nipples. Take a deep breath in for your chest expanded measurement and a deep breath out for your chest relaxed.

Stomach: This is taken around the widest part of your stomach across the belly button.

Waist: This is taken around your hips where your belt sits. Take this while you’re wearing your jeans and belt.

In order to get the most accurate desired sleeve and back lengths for your jacket, we ask you to provide these additional measurements from a jacket that fits you well in these lengths. Ensure any jacket you measure is made from a similar weight material that’s not too stretchy (ideally leather) and fits well across your shoulder without a ‘dropped’ shoulder seam.

Lay the jacket completely flat and measure in a straight line from the bottom of the collar seam (where the collar attaches to the back) to the bottom of the back hem for the back measurement. For the sleeve measurement, slightly fold the sleeves into the body to get a straight line from the shoulder to the cuff then measure in a straight line (do not follow arm curve) from the highest point in shoulder seam to the bottom of the cuff and double check the measurement on the other sleeve.

If you’re unsure about anything, please get in touch and forward us some pictures of you taking your measurements.

Please see the diagram below for advice on taking your measurements.

As well as your height, we need the following body measurements to determine your correct sizing:

Chest Relaxed and Expanded: This is taken around the widest part of your chest across the nipples. Take a deep breath in for your chest expanded measurement and a deep breath out for your chest relaxed.

Stomach: This is taken around the widest part of your stomach across the belly button.

Waist: This is taken around your hips where your belt sits. Take this while you’re wearing your jeans and belt.

In order to get the most accurate desired sleeve and back lengths for your jacket, we ask you to provide these additional measurements from a jacket that fits you well in these lengths. Ensure any jacket you measure is made from a similar weight material that’s not too stretchy (ideally leather) and fits well across your shoulder without a ‘dropped’ shoulder seam.

Lay the jacket completely flat and measure in a straight line from the bottom of the collar seam (where the collar attaches to the back) to the bottom of the back hem for the back measurement. For the sleeve measurement, slightly fold the sleeves into the body to get a straight line from the shoulder to the cuff then measure in a straight line (do not follow arm curve) from the highest point in shoulder seam to the bottom of the cuff and double check the measurement on the other sleeve.

If you’re unsure about anything, please get in touch and forward us some pictures of you taking your measurements.

Please see the diagram below for advice on taking your measurements.

While we are one of the industry leaders in creating people’s dream jackets to their specifications and there are few, if any, who offer the level of flexibility that we do, the service we offer is not a fully tailored one.

After finding the correct size for your selected style, if necessary, we can amend the sleeve and back lengths and can usually make slight adjustments to the shoulder width and body to dial in as close as possible to your perfect fit. However, we are unable to make major alterations to our patterns beyond this.

What can seem like a relatively small adjustment to a style can actually have a cascading effect throughout the positioning of the features of a jacket and result in a prohibitively large amount of pattern and design work – with often less than satisfactory results.

Years of development have gone into getting these styles and their fit as close to perfect as we can, and we hope our customers will trust this advice if we are unable to make a requested alteration - our team of sizing experts are on hand to advise how to get the best fitting leather jacket possible.

After finding the correct size for your selected style, if necessary, we can amend the sleeve and back lengths and can usually make slight adjustments to the shoulder width and body to dial in as close as possible to your perfect fit. However, we are unable to make major alterations to our patterns beyond this.

What can seem like a relatively small adjustment to a style can actually have a cascading effect throughout the positioning of the features of a jacket and result in a prohibitively large amount of pattern and design work – with often less than satisfactory results.

Years of development have gone into getting these styles and their fit as close to perfect as we can, and we hope our customers will trust this advice if we are unable to make a requested alteration - our team of sizing experts are on hand to advise how to get the best fitting leather jacket possible.

While our cutters and machinists are experts in their trades and craft your jackets with a very high level of skill and precision, the nature of what we do and the materials we work with means that working to pinpoint accurate measurements isn’t possible and we have to allow for a half inch (1.27cm) tolerance with all measurements on our jackets.

Unlike cloth or other lighter materials, heavy leather is a material that is unsuitable for making a jacket to an exact set of measurements. This is mainly to the difficulty in folding the leather at the seams which is further complicated by variances in leather thickness - even slight differences in their folding giving variations in the precise measurements of the joined panels. While we try to allow for thicknesses while cutting a jacket, it isn’t possible to guarantee an exact measurement around a body where there are 4-6 folded vertical seams.

Add this to the further slight differences that your material selections make, with both the thickness and flexibility of leather and even the lining affecting the final measurements (as well as slight variances between batches of the same leather).

For these reasons (and the fact that the jacket is entirely handmade), we can only guarantee measurements of a finished jacket to be within half an inch of requirements. This minimal discrepancy means nothing on a leather jacket, a few weeks wear and any leather jacket starts to form itself to the wearer's body and even an inch one way or the other will be hidden in the overall ambiance of a broken in jacket.

Unlike cloth or other lighter materials, heavy leather is a material that is unsuitable for making a jacket to an exact set of measurements. This is mainly to the difficulty in folding the leather at the seams which is further complicated by variances in leather thickness - even slight differences in their folding giving variations in the precise measurements of the joined panels. While we try to allow for thicknesses while cutting a jacket, it isn’t possible to guarantee an exact measurement around a body where there are 4-6 folded vertical seams.

Add this to the further slight differences that your material selections make, with both the thickness and flexibility of leather and even the lining affecting the final measurements (as well as slight variances between batches of the same leather).

For these reasons (and the fact that the jacket is entirely handmade), we can only guarantee measurements of a finished jacket to be within half an inch of requirements. This minimal discrepancy means nothing on a leather jacket, a few weeks wear and any leather jacket starts to form itself to the wearer's body and even an inch one way or the other will be hidden in the overall ambiance of a broken in jacket.

If you have any sizing issues once your jacket arrives, please email us with your issues and along with a couple of pictures (front, back and side views) with you wearing the jacket. This is ideally done by someone else or on a timer. We will then discuss the next steps with you.

Leather

We are often asked what is better – Horsehide or Steerhide? While some people will swear by one or the other, the truth is that both result in stunning, high quality leathers. Each has slightly different properties which may or may not be important in making your decision. Again, these are general rules of thumb – there are many other factors that account for the properties of any given leather:

Horsehide

In the 1980’s, we led the way in reviving the use of Horsehide for leather jackets – a material scarcely used since the early-mid 20th century. Over the years, Horsehide jackets and Aero have become synonymous, and it’s still accounts for the majority of jackets we make. Generally, although the skins are a bit lighter and less thick, Horsehide has a denser fibre structure than Steerhide. This tough composition makes it more resistant to stretching and abrasion, therefore taking longer to break-in. The follicles on a horse are also smaller meaning it’s a bit more water repellent than Steerhide. It usually has a slightly coarser, but less prevalent grain with a lot more variation than Steerhide, although the Front Quarter Horsehide we use is more consistent than skins from other parts of the animal.

Steerhide

Steerhide/Cowhide is the most widely used leather throughout the world – it’s readily available with a large useable area and is very versatile. Relative to Horsehide, skins of the same weight category are a bit heavier and thicker (although not always the case), however it usually takes less time to break in than Horsehide due to its less dense fibre structure. It normally has consistent grain throughout the hide which is more pronounced than Horsehide and which develops beautifully with age.

Goatskin

Not to be overlooked when deciding your leather – especially for those looking for the toughest leather they can get without the need for a long break in! It is very breathable, yet has amongst the best natural water resistance properties of any hide (which is why most Navy jackets were made from Goatskin). Compared with Horse and Steer, Goatskin develops/ages more slowly although still has the potential to yield a beautiful patina with a lot of wear. As tough and durable as Goatskin is, it is very soft to the touch and is remarkably supple compared to most Horsehides and Steerhides, so it’s incredibly comfortable to wear straight away and requires very little break in. It almost always has a very pronounced ‘pebbled’ grain which really adds to the unique feel and properties of this leather.

Horsehide

In the 1980’s, we led the way in reviving the use of Horsehide for leather jackets – a material scarcely used since the early-mid 20th century. Over the years, Horsehide jackets and Aero have become synonymous, and it’s still accounts for the majority of jackets we make. Generally, although the skins are a bit lighter and less thick, Horsehide has a denser fibre structure than Steerhide. This tough composition makes it more resistant to stretching and abrasion, therefore taking longer to break-in. The follicles on a horse are also smaller meaning it’s a bit more water repellent than Steerhide. It usually has a slightly coarser, but less prevalent grain with a lot more variation than Steerhide, although the Front Quarter Horsehide we use is more consistent than skins from other parts of the animal.

Steerhide

Steerhide/Cowhide is the most widely used leather throughout the world – it’s readily available with a large useable area and is very versatile. Relative to Horsehide, skins of the same weight category are a bit heavier and thicker (although not always the case), however it usually takes less time to break in than Horsehide due to its less dense fibre structure. It normally has consistent grain throughout the hide which is more pronounced than Horsehide and which develops beautifully with age.

Goatskin

Not to be overlooked when deciding your leather – especially for those looking for the toughest leather they can get without the need for a long break in! It is very breathable, yet has amongst the best natural water resistance properties of any hide (which is why most Navy jackets were made from Goatskin). Compared with Horse and Steer, Goatskin develops/ages more slowly although still has the potential to yield a beautiful patina with a lot of wear. As tough and durable as Goatskin is, it is very soft to the touch and is remarkably supple compared to most Horsehides and Steerhides, so it’s incredibly comfortable to wear straight away and requires very little break in. It almost always has a very pronounced ‘pebbled’ grain which really adds to the unique feel and properties of this leather.

Yes, there is a listing to request leather samples here.

You can order a maximum of five samples per order and there is a small charge per sample with postage payable on top of this cost.

You can order a maximum of five samples per order and there is a small charge per sample with postage payable on top of this cost.

The leathers we use at Aero are top grade ‘full-grain’ leathers. ‘Full-grain’ doesn’t necessarily refer to the amount of grain you can expect in a hide, but it refers to which part of the hide is used and how it is processed before tanning.

While full-grain leather uses the entirety of the uppermost grain layer of the animal’s hide and goes straight into the tanning process without any further treatment after hair removal, lower grades (which make up the vast majority of leather in the world) use different parts of the skin and have additional processing carried out beforehand.

“Top-grain” leathers for example (the next grade down from full-grain) have often been sanded down to create more surface uniformity and increase workability with the leather, giving a manufacturer a fresh top surface to apply a variety of finishes. While top grain leather can still be high quality and is used to produce many high-end luxury goods, the future patina and durability of the leather is compromised in the process of removing the very top layer of the skin.

‘Split’ leather is an umbrella term for most of the leather in the world which is created from inner skin layer (the corium) after it is split from the top grain layer. This kind of leather is more pliable and versatile than full grain leather and can be processed in a variety of ways such as artificially embossing grain (known as corrected-grain leather). While still advertised as “genuine” leather, these leathers are of lower quality, durability and they lose their natural beauty, feel and development potential.

But because the entire thickness of the skin is used in full-grain leather, it’s a lot stronger and more durable than leather that has been ‘split’ or ‘shaved’ and because all of the original characteristics of the leather and oil absorbing properties are retained from the uppermost layer of the skin, the leather will develop a beautiful natural patina over time. Because they retain this natural beauty and impressively withstand the demands of time, and because only the best hides can be used due to their authentic unprocessed nature, full-grain leathers come with a higher price tag than other grades, but one that is definitely justified by the end result.

While full-grain leather uses the entirety of the uppermost grain layer of the animal’s hide and goes straight into the tanning process without any further treatment after hair removal, lower grades (which make up the vast majority of leather in the world) use different parts of the skin and have additional processing carried out beforehand.

“Top-grain” leathers for example (the next grade down from full-grain) have often been sanded down to create more surface uniformity and increase workability with the leather, giving a manufacturer a fresh top surface to apply a variety of finishes. While top grain leather can still be high quality and is used to produce many high-end luxury goods, the future patina and durability of the leather is compromised in the process of removing the very top layer of the skin.

‘Split’ leather is an umbrella term for most of the leather in the world which is created from inner skin layer (the corium) after it is split from the top grain layer. This kind of leather is more pliable and versatile than full grain leather and can be processed in a variety of ways such as artificially embossing grain (known as corrected-grain leather). While still advertised as “genuine” leather, these leathers are of lower quality, durability and they lose their natural beauty, feel and development potential.

But because the entire thickness of the skin is used in full-grain leather, it’s a lot stronger and more durable than leather that has been ‘split’ or ‘shaved’ and because all of the original characteristics of the leather and oil absorbing properties are retained from the uppermost layer of the skin, the leather will develop a beautiful natural patina over time. Because they retain this natural beauty and impressively withstand the demands of time, and because only the best hides can be used due to their authentic unprocessed nature, full-grain leathers come with a higher price tag than other grades, but one that is definitely justified by the end result.

For decades we’ve been traditionally associated with ‘heavy’ leather jackets made from Horween’s Chromexcel® Leather, but we also carry a wide range of lighter leathers that are generally categorised as ‘midweight’ leathers.

Please note, while we categorise these leathers as ‘midweight’ and ‘lighter’, this is relative to Chromexcel® which is a particularly heavy leather. Many of these leathers are still heavier than high street leathers many are accustomed to, and we can guarantee they are more substantial and higher quality (almost no high street leathers are full-grain).

While some people may adopt a ‘heavier is better’ attitude towards leather, as long as the leathers being compared are full-grain, weight is not really indicative of the ultimate ‘quality’ of a leather – it’s simply one attribute (albeit an important one) to consider when making your leather choice.

‘Midweight’ leather will be easier to wear, taking less time to break in and may be more appropriate for warmer climates, whereas a heavier leather may be better suited for a motorcycle/winter jacket for added protection and those who want to really feel the weight of their jacket on their shoulders and don’t mind a long break-in period.

The spectrum of weight runs from our lightest midweight leather ‘Battered Steerhide’ with a general weight of 2oz, to our heaviest leather, Horween’s ‘Chromexcel’ Steerhide with a general weight of 4oz.

However, these categorisations are a very general guide - there is quite a bit of variation within the midweight category (Vicenza wears quite a bit heavier than Battered Steerhide for example) and even within the same leather, because the leather is full grain without any leather splitting, different hides of the same leather can vary in thickness and weight.

Please note, while we categorise these leathers as ‘midweight’ and ‘lighter’, this is relative to Chromexcel® which is a particularly heavy leather. Many of these leathers are still heavier than high street leathers many are accustomed to, and we can guarantee they are more substantial and higher quality (almost no high street leathers are full-grain).

While some people may adopt a ‘heavier is better’ attitude towards leather, as long as the leathers being compared are full-grain, weight is not really indicative of the ultimate ‘quality’ of a leather – it’s simply one attribute (albeit an important one) to consider when making your leather choice.

‘Midweight’ leather will be easier to wear, taking less time to break in and may be more appropriate for warmer climates, whereas a heavier leather may be better suited for a motorcycle/winter jacket for added protection and those who want to really feel the weight of their jacket on their shoulders and don’t mind a long break-in period.

The spectrum of weight runs from our lightest midweight leather ‘Battered Steerhide’ with a general weight of 2oz, to our heaviest leather, Horween’s ‘Chromexcel’ Steerhide with a general weight of 4oz.

However, these categorisations are a very general guide - there is quite a bit of variation within the midweight category (Vicenza wears quite a bit heavier than Battered Steerhide for example) and even within the same leather, because the leather is full grain without any leather splitting, different hides of the same leather can vary in thickness and weight.

Tanning is the process of treating and preserving hides (from larger animals) or skins (from smaller animals) to produce long-lasting useable leather.

Hides and skins are usually either ‘Chrome Tanned’ or ‘Vegetable Tanned’ (or a combination of both) to produce leather.

Hides and skins are usually either ‘Chrome Tanned’ or ‘Vegetable Tanned’ (or a combination of both) to produce leather.

Vegetable Tanning was the original (and up until the 19th century, the only) method of producing leather. For thousands of years, our ancestors developed and used variations of the same basic process to turn their raw animal hides into essential long-lasting leather and while modern methods are more refined and scientific, the main principles remain the same.

Vegetable tanning involves the use of tannin, a naturally occurring compound that is found in plant sources like bark, roots and leaves. A hide is stretched on a wooden frame and over time, soaked in an increasingly concentrated solution of these plant extracts/tannic acids. The tannins displace water molecules bound to the hide’s collagen (it’s main structural protein) and take the place of the removed water. The process is long and complex, taking anything between a few months to a few years and requiring the work of highly skilled craftsmen to ensure the tannin molecules replace the water molecules in just the right way to produce durable and well preserved leather. Because of the skill and time involved in its production, Vegetable Tanned leather is rarer than Chrome Tanned leather – only 10% of leather produced is Vegetable Tanned. This natural tanning process is also relatively environmentally friendly (although it does use a fair amount of water).

Vegetable tanning involves the use of tannin, a naturally occurring compound that is found in plant sources like bark, roots and leaves. A hide is stretched on a wooden frame and over time, soaked in an increasingly concentrated solution of these plant extracts/tannic acids. The tannins displace water molecules bound to the hide’s collagen (it’s main structural protein) and take the place of the removed water. The process is long and complex, taking anything between a few months to a few years and requiring the work of highly skilled craftsmen to ensure the tannin molecules replace the water molecules in just the right way to produce durable and well preserved leather. Because of the skill and time involved in its production, Vegetable Tanned leather is rarer than Chrome Tanned leather – only 10% of leather produced is Vegetable Tanned. This natural tanning process is also relatively environmentally friendly (although it does use a fair amount of water).

Vegetable Tanning’s production time, complexity and expense and the industry demand for a more time-efficient and less costly solution led to the development of ‘Chrome Tanning’ in the mid-19th century.

The basic tanning principle is the same: to remove and replace water molecules from the collagen of the skin. However, Chrome Tanning replaces the water with chromium salts instead of tannins.

The process involves placing pre-treated hides in baths and drums that contain the chromium sulphates as well as acids and other chemicals which ensure the chrome better fits in between the collagen molecules, before returning the hides to a normal pH level.

It’s quicker turnaround, durability, and the huge variety of leathers with different properties that could be made with Chrome Tanning saw it quickly become the world’s preferred method of tanning, allowing leather to become a staple in almost every clothing genre – from everyday workwear to large military contracts during the WW2 period. To this day, around 90% of the world’s leather is Chrome Tanned.

It does however have a far greater environmental impact than Vegetable Tanning, although over the years as this impact was better understood, many tanneries are now subject to strict environmental regulations and take measures to reduce this impact (the Chromexcel® leather that we get from Horween in Chicago being a good example).

The basic tanning principle is the same: to remove and replace water molecules from the collagen of the skin. However, Chrome Tanning replaces the water with chromium salts instead of tannins.

The process involves placing pre-treated hides in baths and drums that contain the chromium sulphates as well as acids and other chemicals which ensure the chrome better fits in between the collagen molecules, before returning the hides to a normal pH level.

It’s quicker turnaround, durability, and the huge variety of leathers with different properties that could be made with Chrome Tanning saw it quickly become the world’s preferred method of tanning, allowing leather to become a staple in almost every clothing genre – from everyday workwear to large military contracts during the WW2 period. To this day, around 90% of the world’s leather is Chrome Tanned.

It does however have a far greater environmental impact than Vegetable Tanning, although over the years as this impact was better understood, many tanneries are now subject to strict environmental regulations and take measures to reduce this impact (the Chromexcel® leather that we get from Horween in Chicago being a good example).

This method involves some combination of Chrome Tanning and Vegetable Tanning and seeks to strike a balance by capturing some of the advantages of both individual methods. Some of our leathers like Kelpie and most famously, Horween’s Chromexcel®, have their own methods of combination tanning (mostly Vegetable Tanned with a quicker final Chrome Tannage to help lock in the waxes and colour).

Although some have strong individual preferences for one or the other and either method may produce more ideally suited leather depending on the situation and buyer, neither method produces inherently ‘better’ leather – just leather with different properties. Speaking very broadly, Chrome Tanning allows for softer and more supple leather (with relatively less breaking-in required) which is more resistant to the elements and will retain colour consistency for longer. It won’t patina as fast or to the same degree as Vegetable Tanned leather.

Vegetable Tanned leather’s organic nature means it patinas more quickly and dramatically, reacting to exposure to the elements more than Chrome Tanned leather. Although stiffer and firmer to begin with, Vegetable Tanned leather’s hand and feel also develops substantially, softening up or ‘breaking in’ with wear. Chrome Tanned leathers also go through this process to varying degrees, but often don’t develop as much in this regard or require as much breaking in.

Many consider Vegetable Tanned leather as more desirable than Chrome Tanned leather because of the general increase in the time and skill required to produce it. While often true, this can be a misleading generalisation. While it’s true that because it’s faster to produce, many (but not all) lesser quality leathers are likely Chrome Tanned, this does not mean all Chrome Tanned leathers are lesser quality. Some of the best quality leathers we’ve worked with over the years have been Chrome Tanned. Like everything, there is a spectrum of quality in the leather produced using each method and rest assured, we only use the very best from each.

What really matters is what you’re looking for from your leather – do you want a Vegetable Tanned leather’s ever-developing story that its gorgeous patina tells over the years? Or is a Chrome Tanned leather’s suppleness and relative consistency more important to you? In any case, the tannage is just one factor in determining the properties of any given leather. The type of hide, it’s weight and the method of finishing the leather are just some of the other factors which determine a leather’s properties.

Vegetable Tanned leather’s organic nature means it patinas more quickly and dramatically, reacting to exposure to the elements more than Chrome Tanned leather. Although stiffer and firmer to begin with, Vegetable Tanned leather’s hand and feel also develops substantially, softening up or ‘breaking in’ with wear. Chrome Tanned leathers also go through this process to varying degrees, but often don’t develop as much in this regard or require as much breaking in.

Many consider Vegetable Tanned leather as more desirable than Chrome Tanned leather because of the general increase in the time and skill required to produce it. While often true, this can be a misleading generalisation. While it’s true that because it’s faster to produce, many (but not all) lesser quality leathers are likely Chrome Tanned, this does not mean all Chrome Tanned leathers are lesser quality. Some of the best quality leathers we’ve worked with over the years have been Chrome Tanned. Like everything, there is a spectrum of quality in the leather produced using each method and rest assured, we only use the very best from each.

What really matters is what you’re looking for from your leather – do you want a Vegetable Tanned leather’s ever-developing story that its gorgeous patina tells over the years? Or is a Chrome Tanned leather’s suppleness and relative consistency more important to you? In any case, the tannage is just one factor in determining the properties of any given leather. The type of hide, it’s weight and the method of finishing the leather are just some of the other factors which determine a leather’s properties.

Leather dyes penetrate and are in the leather, accentuating the natural variations in the hides (some areas perhaps being darker and lighter). Leather paints/pigments on the other hand, coat the fibre and are on the leather.

Aniline leather is leather which has been dyed but has not received any pigment in it’s finish. This approach is for the purists who want the most authentic look from their leather, where as much of the original hide’s character and variation is retained as possible. The leather may be afforded some protection by its fully translucent finish, but it is more susceptible to the elements and markings/fading over time than semi-aniline leathers (which is what gives these leathers their beautiful patina). Aniline leathers that we use include ‘Badalassi’ Steerhide, ‘Kelpie’ Horsehide and Horween’s Chromexcel® leathers.

Semi-aniline leather is also aniline dyed, but it’s finish also incorporates a small amount of pigment on the leather (but not so much that it conceals the hide’s natural characteristics). This approach allows for a more consistent colour throughout a hide, as well as more protection from fading and marking over time while still retaining much of the hide’s natural beauty, although the trade-off is that a small amount of the original hide’s character and natural development is sacrificed for this consistency. Semi-aniline leathers that we carry include ‘Vicenza’ Horsehide and ‘Jerky’ Horsehide.

Aniline leather is leather which has been dyed but has not received any pigment in it’s finish. This approach is for the purists who want the most authentic look from their leather, where as much of the original hide’s character and variation is retained as possible. The leather may be afforded some protection by its fully translucent finish, but it is more susceptible to the elements and markings/fading over time than semi-aniline leathers (which is what gives these leathers their beautiful patina). Aniline leathers that we use include ‘Badalassi’ Steerhide, ‘Kelpie’ Horsehide and Horween’s Chromexcel® leathers.

Semi-aniline leather is also aniline dyed, but it’s finish also incorporates a small amount of pigment on the leather (but not so much that it conceals the hide’s natural characteristics). This approach allows for a more consistent colour throughout a hide, as well as more protection from fading and marking over time while still retaining much of the hide’s natural beauty, although the trade-off is that a small amount of the original hide’s character and natural development is sacrificed for this consistency. Semi-aniline leathers that we carry include ‘Vicenza’ Horsehide and ‘Jerky’ Horsehide.